Project Description

2015-present

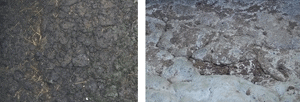

Surface of non-foaming (left) and foaming (right) manure storage.

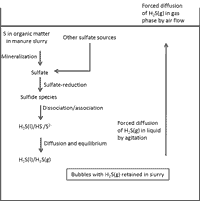

This study will evaluate hydrogen sulfide occurrence and transfer process during manure agitation of deep-pit storage. Manure will be sampled from foaming and non-foaming barns at different depth of the pit before and during manure agitation and pumping, and tested for the capability of hydrogen sulfide generation and gas bubble retention. Gas samples will also be collected at different sites of the barns. These samples will be analyzed for the spatial and temporal distributions of sulfide species. With this approach, the sulfide generation and transfer process due to agitation can be determined. The results will be important for controlling hydrogen sulfide during agitation and for reducing the risk of workers and animal death accidents, therefore, improving the agricultural safety and health in manure management systems.

This study will evaluate hydrogen sulfide occurrence and transfer process during manure agitation of deep-pit storage. Manure will be sampled from foaming and non-foaming barns at different depth of the pit before and during manure agitation and pumping, and tested for the capability of hydrogen sulfide generation and gas bubble retention. Gas samples will also be collected at different sites of the barns. These samples will be analyzed for the spatial and temporal distributions of sulfide species. With this approach, the sulfide generation and transfer process due to agitation can be determined. The results will be important for controlling hydrogen sulfide during agitation and for reducing the risk of workers and animal death accidents, therefore, improving the agricultural safety and health in manure management systems.

Human and animal exposure to hydrogen sulfide in animal barns has long been a severe issue due to its acute and chronic toxicity.